46

INDOFOOD AGRI RESOURCES LTD

SUSTAINABILITY REPORT 2014

and diligent supervision also ensures that no effluent enters the

riparian areas as surface run

-

off.

We have enhanced the handling of POME in three mills using

the open

-

window Aerated Bunker Composting System. For more

information, please read our fertiliser section on page 43.

REFINERY EFFLUENTS

All refinery effluent is properly treated by wastewater treatment

plants to ensure the effluent BOD level and other indicators

are within the legal limits before being discharged into the

river, sea or sewer. In 2014, the volume of discharged water

was 256,806 m

3

and the average BOD level of the discharged

wastewater in four refineries was 15.68 mg/L, which was

below the regulatory limit of 75 mg/L.

OIL SPILLS

We have established stringent procedures on the transport of

CPO from the factories to the storage tanks to prevent CPO

spillage. The same procedures also apply to the transport and

storage of diesel fuel by the operations teams.

During the year, one CPO spillage incident was reported. The

incident occurred during a bad weather on the Java Sea when

the CPO was transported from our storage tank to the refinery

by a third

-

party logistics supplier. 70 tonnes of CPO were lost at

sea with no associated negative environmental impacts. We have

communicated with the logistics supplier concerned to handle

the spillage properly and responsibly.

We are currently reviewing our policies to address any gaps in

the area of oil spill management, including services that are to

be performed by third

-

party suppliers. We are also developing

measures to avoid similar incidents, and to provide guidelines on

the proper transportation of palm oil by sea vessels.

No fines or sanctions related to environmental regulations were

imposed on IndoAgri in 2014.

WATER, EFFLUENTS

AND SPILLS

WATER

Water is crucial to the healthy growth of crops in our plantations,

as well as the daily operations of our estates, mills and refineries.

Clean drinking water is also required to sustain the well being of

every person in our estates, mills and refineries.

Our plantations are generally watered by the seasonal rainfalls.

The mills receive 95% of their water supply from nearby

rivers, and the rest from groundwater. Water for domestic use

in plantation offices and living facilities is drawn mainly from

rainwater as well. To facilitate access to water sources, we

have constructed dams and wells to ensure a steady supply

of water. The refineries obtain 78% of their water requirement

from municipal water and the rest from groundwater.

Before a plantation is developed, it is compulsory to perform

an Environmental Impact Assessment, known as AMDAL. The

assessment will determine the impact of the water usage to rivers

and groundwater levels. All our plantation sites have passed the

AMDAL assessment. Water sources that are important for the

local wildlife and surrounding communities will be identified

under the HCV assessment, and assigned as an HCV area.

The water consumption for processing our products in our

refineries and mills is tabulated above. The data excludes

insignificant amount of water drawn frommunicipal sources, such

as ground water for domestic usage. Calculations are based on

metered volumes.

Table of Water Consumption in Mills and Refineries

Water Consumption

Consumption (m

3

)

Ratio (m

3

/tonne)

Palm Oil Mills

2012

3,469,080

0.96

2013

3,183,974

0.98

2014

3,488,902

0.98

Note 1: Data recorded from RSPO and PROPER audited or certified oil palm

mills (77%). Water consumption ratio covers industrial usage per mill.

Note 2: Ratio is calculated based on average consumption in m

3

per tonne of

FFB processed.

Refineries

2012

723,373

0.52

2013

737,645

0.50

2014

709,893

0.42

Note: Data recorded from four refineries (80%) based on water consumption ratio

per tonne material processed and product in four process stations (refining CPO,

fractionation, margarine, cooking oil filling).

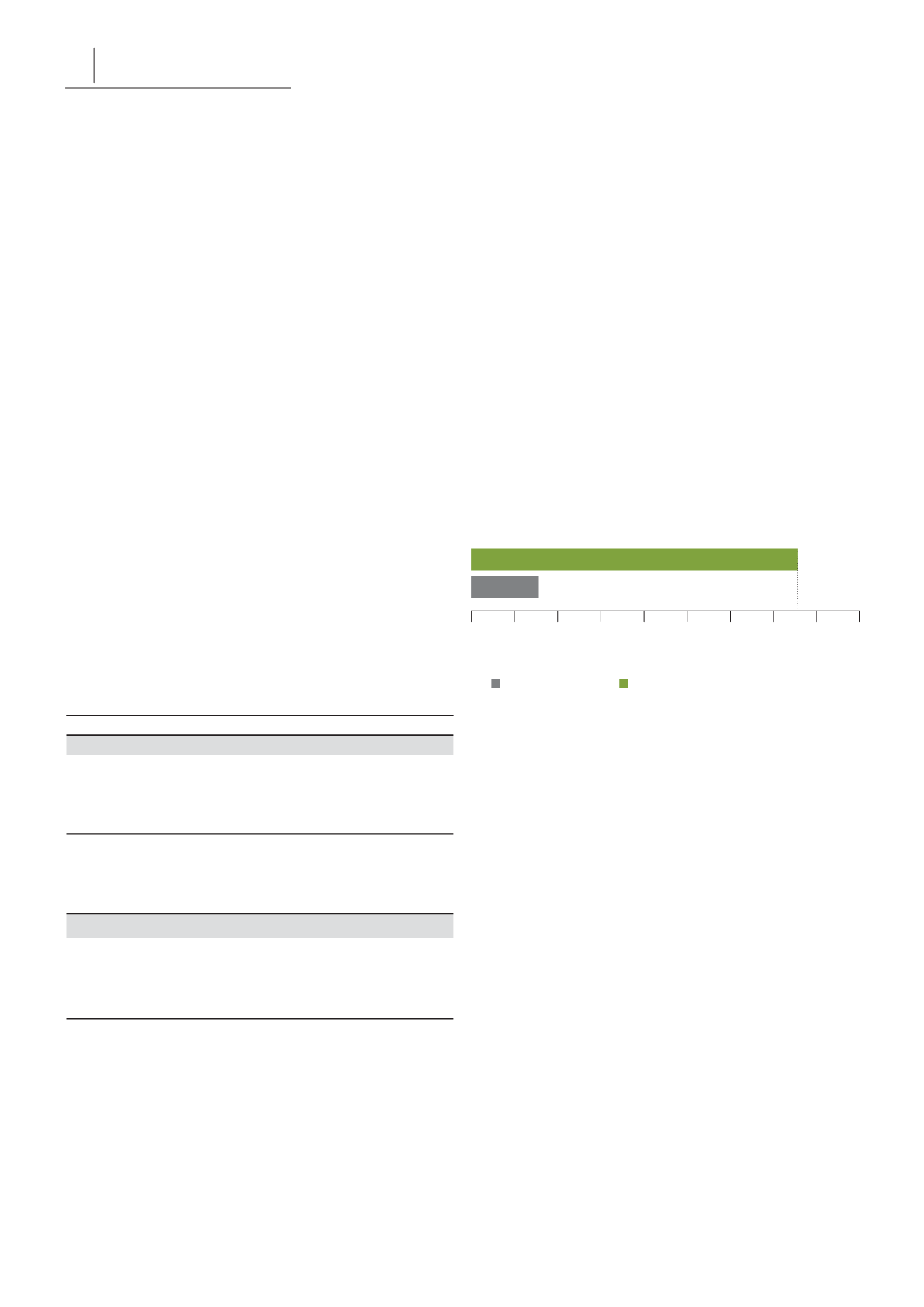

Average BOD Level of Refinery Effluents

MILL EFFLUENTS

POME, a by-product from the milling process, is recycled as

organic fertilisers for the plantations. The POME is collected and

treated in open anaerobic ponds on the estates. Plantation teams

will check and adjust the conditions of the ponds every month to

maintain the Biological Oxygen Demand (BOD) level within the

legal limit of 5,000 mg/L for effluent land application. Careful

15.68

75

Maximum Limit on Government Regulation

BOD Average

Note: Data from four refineries (80%).

0 10 20 30 40 50 60 70 80

BOD Level (mg/L)